Precise dressing, renewal! This diamond high-precision grinding wheel dresser is designed for industrial scenarios such as mechanical manufacturing, mold processing, hardware production, and tool grinding, as well as professional processing needs. Featuring a high-hardness diamond tip and precision structural design, it easily solves problems like grinding wheel dullness, uneven wear, and contour deformation—quickly restoring the wheel’s sharp cutting performance and accurate geometric shape. It’s the core auxiliary tool to ensure grinding quality and improve production efficiency.

The dresser’s key component—the tip is made of natural/synthetic diamond, with a hardness exceeding HV10000, far higher than the abrasive grains of ordinary grinding wheels. Wear-resistant and impact-resistant, it won’t easily wear or crack even when in long-term contact with high-speed rotating wheels. Its service life is 5-8 times that of ordinary alloy dressers. The body is crafted from high-quality chromium-vanadium steel (Cr-V) via one-piece forging, undergoing dual heat treatment (high-temperature quenching + low-temperature tempering) to reach a hardness of HRC45-50. It boasts a stable structure and strong deformation resistance, capable of withstanding high-frequency use in workshops and processing plants, adapting to complex working environments.

Core dressing advantages combine precision and efficiency:

- 2-in-1 truing and sharpening: The sharp diamond tip quickly removes dull abrasive grains and excess bonding agents from the wheel surface. It not only reshapes the wheel into custom contours (such as straight edges, convex arcs, concave arcs) but also cleans blockages between grains—achieving “truing + sharpening” simultaneously. The wheel instantly regains its original sharpness and flatness, avoiding workpiece burns and rough surfaces.

- Ultra-high precision control: Equipped with a precision adjustment structure, the dressing accuracy is as low as 0.01mm. It ensures uniform wheel thickness and qualified side parallelism, guaranteeing consistent dimensions of workpieces in subsequent grinding. Ideal for high-precision needs like mold processing and precision part production.

- Compatible with multiple wheel types: Works with ordinary aluminum oxide wheels, silicon carbide wheels, as well as super-hard cubic boron nitride (CBN) wheels and diamond wheels. One dresser handles various grinding wheel dressing tasks, eliminating frequent tool changes and reducing procurement costs.

User-friendly design for diverse scenarios:

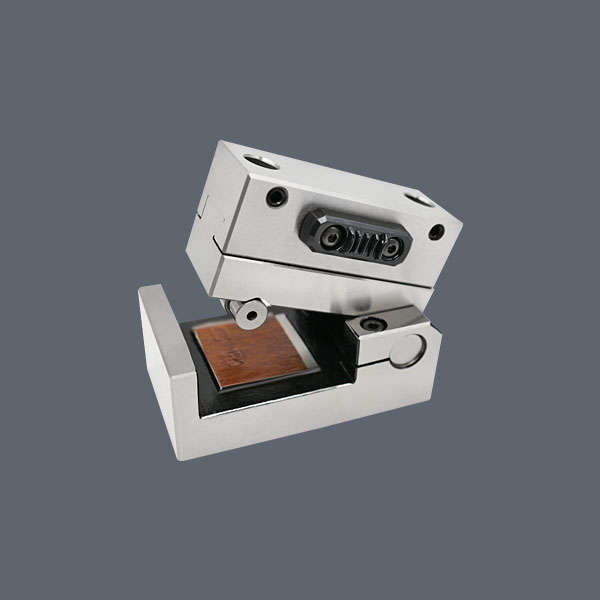

- Multiple types to choose from: Bench-mounted models are fixed on grinders for high-precision mass production; handheld models offer flexible operation, suitable for small grinders and temporary dressing needs; single-edge models focus on fine truing, while multi-edge models deliver higher efficiency—choose based on actual work requirements.

- Easy adjustment and installation: Bench-mounted models feature a calibrated adjustment knob for intuitive and precise angle/depth control; handheld models adopt an ergonomic non-slip handle for comfortable grip and smooth force application, reducing hand fatigue during prolonged use. The standard installation interface is compatible with most surface grinders and universal tool grinders on the market, enabling quick and easy installation/removal.

- Durable protection design: The tip uses an inlaid fixed structure for secure connection without falling off; the body surface undergoes oxide blackening anti-rust treatment, resisting oil pollution and moisture erosion in workshops. It won’t rust easily during long-term storage and use, ensuring long-lasting durability.

Widely applicable scenarios: Suitable for mass part grinding in mechanical manufacturing, precise cavity dressing in mold processing, hardware accessory production, tool edge grinding, and precision instrument part processing. Whether you’re running a large-scale production line or handling professional small-batch processing, this diamond high-precision grinding wheel dresser delivers reliable performance. It helps maintain consistent grinding quality, reduces production downtime caused by worn wheels, and boosts overall work efficiency—becoming an indispensable tool for professional technicians and manufacturing plants.

评价

目前还没有评价