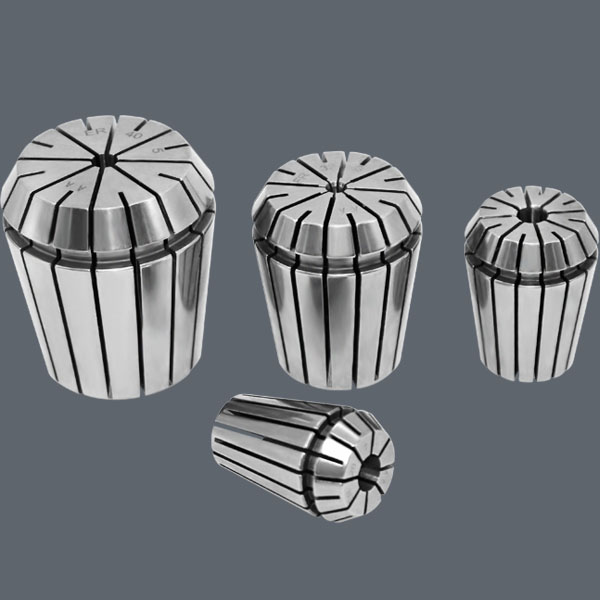

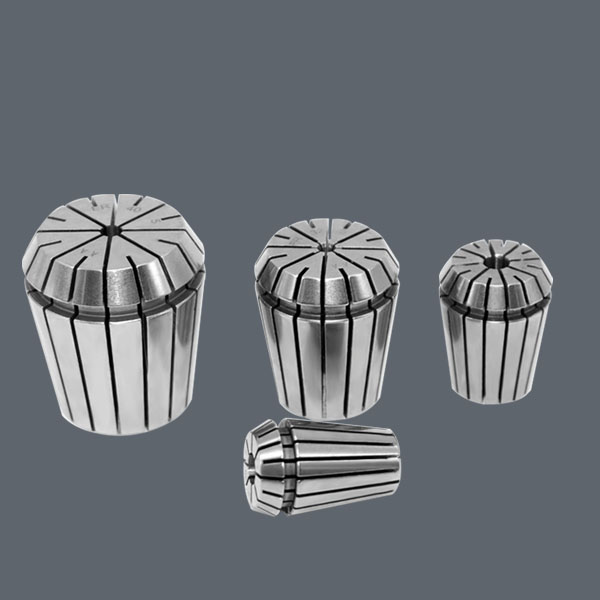

Precision clamping, millimeter-perfect control! This CNC high-precision ER collet is tailor-made for CNC machining centers, engraving machines, milling machines, drilling and tapping machines, and other numerical control equipment. As a core fixture accessory for holding cutting tools such as end mills, drill bits, taps, and engraving cutters, it achieves micron-level tool positioning and powerful locking through its precision elastic structure and top-tier manufacturing craftsmanship. It fundamentally solves common CNC machining problems like tool runout, slipping, and falling during high-speed cutting, providing reliable support for high-precision operations including mold processing, precision part manufacturing, and 3C electronic component machining. It is an indispensable tool to enhance machining accuracy and production efficiency.

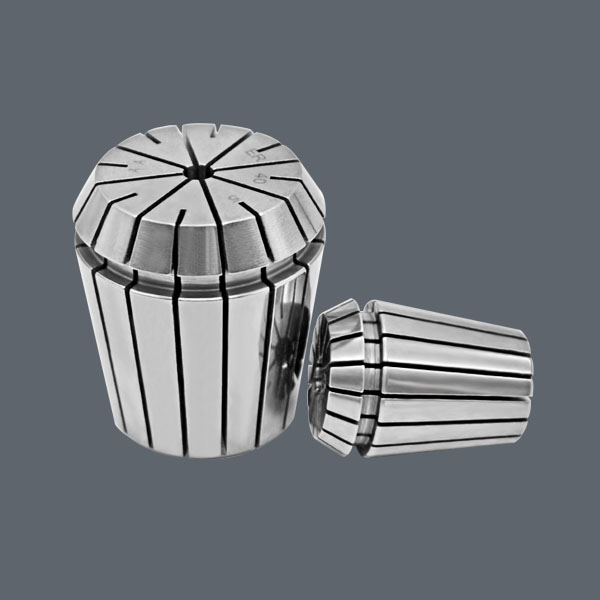

Crafted from premium 65Mn spring steel via precision forging—far superior to ordinary carbon steel—the collet undergoes triple heat treatment processes: high-temperature quenching, low-temperature tempering, and stress relief. Boasting a hardness rating of HRC 48-52, it delivers uniform elasticity and excellent toughness. The spacing and thickness of the collet slots are precisely calculated to ensure synchronous contraction when locked, generating strong and evenly distributed clamping force. Even under extreme machining conditions with high rotational speeds (up to tens of thousands of RPM) and heavy cutting loads, the collet firmly grips the tool shank, eliminating risks of slippage and tool falling, and ensuring safe and stable machining processes.

Core precision advantages target key CNC machining pain points:

- Ultra-high clamping accuracy: The inner bore is finished by 5-axis precision grinding and polishing, achieving a surface roughness of Ra 0.2μm or less, with a total indicator runout (TIR) as low as 0.003mm-0.01mm. It fits seamlessly with tool shanks, effectively suppressing tool runout during high-speed rotation. This prevents workpiece dimensional deviations, surface burrs, and tool chipping caused by tool wobbling, meeting the ultra-high precision requirements of mold cavity machining and precision hardware part manufacturing.

- Full coverage of standardized specifications: Strictly compliant with international ER standards, it includes a complete range of models from ER8 to ER32, with clamping diameters spanning 0.5mm to 32mm. Compatible with straight-shank end mills, drill bits, taps, and various other cutting tools, it works with most CNC spindles on the market. Installation and disassembly are hassle-free without additional equipment debugging, ensuring exceptional versatility.

- Wear and corrosion resistance design: The inner bore surface is treated with hard chrome plating, increasing hardness to over HV800. This reduces friction wear between the collet and tool shank, extending the service life of both the collet and tools. The entire collet undergoes anti-rust passivation treatment, resisting long-term erosion from cutting fluids and oil stains. It remains rust-free and deformation-resistant even in humid machining environments, significantly reducing replacement frequency and saving machining costs.

User-friendly details meet diverse machining needs:

- Precision concentricity design: The collet taper achieves over 98% fit with the collet nut. Once locked, concentricity remains stable, ensuring precise tool rotation paths, improving workpiece surface finish, and reducing subsequent polishing procedures.

- Stable elastic rebound: The collet slots pass repeated fatigue tests, withstanding tens of thousands of clamping-release cycles without failure. Elastic rebound performance remains consistent, maintaining accuracy over long-term use.

- Portable classified storage: Comes with a storage case clearly marked with specifications. Collets of different models and clamping ranges are organized separately for easy identification and access, facilitating workshop management and quick tool changes.

Widely applicable in professional scenarios: Whether it’s high-precision mold cavity milling in die shops, drilling and tapping of hardware parts in precision machinery factories, micro-component machining in 3C electronics plants, or fine engraving on woodworking engraving machines, this CNC high-precision ER collet delivers reliable performance. With core advantages of micron-level precision, strong clamping force, and long service life, it becomes a trusted partner in CNC machining, empowering accurate and efficient operations and ensuring consistent product quality output every time!

评价

目前还没有评价