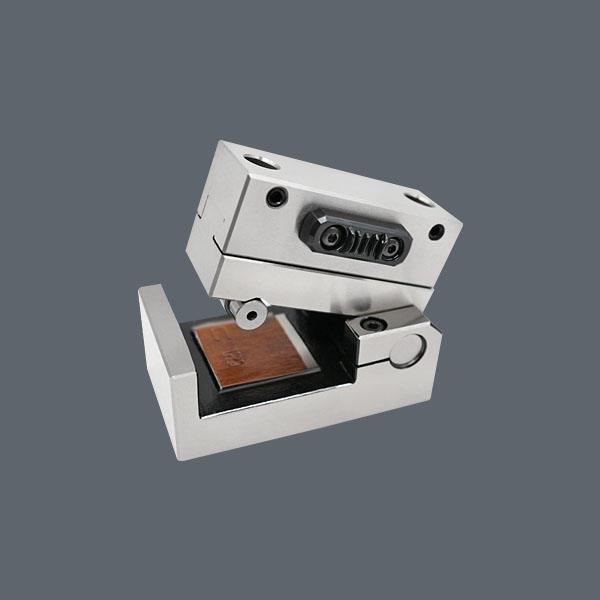

AP50 Angular Sine Wheel Dresser: Professional-Grade Precision Grinding Solution

In high-end machining scenarios such as mold manufacturing, precision part production, and tool regrinding, the accurate dressing of grinding wheels is a core link to ensure the surface finish and dimensional accuracy of workpieces. As a professional-grade tool, the AP50 Angular Sine Wheel Dresser redefines the standard for wheel dressing with its high-precision sine bar mechanism and excellent structural design, injecting stable and efficient precision into your machining process.

Core Advantages: Dual Breakthroughs in Precision and Durability

1. Micron-Level Precision with Unmatched Consistency

Integrated with a high-precision sine bar mechanism, it enables fine angle adjustment from 0° to 60°, and the angle accuracy is strictly controlled within ≤±0.002mm. The repeatability fully meets the requirements of high-end machining environments. Whether for complex contour dressing or standardized grinding operations, it can stably maintain angle consistency, fundamentally avoiding workpiece scrapping caused by wheel dressing errors and significantly improving product qualification rates.

2. Military-Grade Material for Time-Tested Durability

Crafted from high-quality alloy steel through integral forging, it undergoes overall quenching (HRC58-62) and full-process precision grinding. Its surface hardness and wear resistance are far superior to ordinary dressers. Even in high-frequency and high-intensity continuous operations, it can resist wear and deformation, maintaining stable performance for a long time, effectively reducing the frequency of equipment replacement, and saving long-term procurement costs for enterprises.

3. Flexible Adaptation for Seamless Compatibility Across Scenarios

With a compact and robust structural design (dimensions: 87×50 (φ)×73mm, weight: approx. 1.4kg), it can be easily installed on various vertical and horizontal machine tools, and put into use without complex modifications. Whether it is a single-machine operation in a small processing workshop or assembly line production in a large factory, it can flexibly integrate into the existing equipment system, and its performance is not affected by the installation method.

Six Core Features: Efficient Operation for Convenience

- Dual-Purpose Design: Supports both vertical and horizontal application scenarios, capable of handling various operational needs such as wheel surface dressing and angle grinding. One device meets the requirements of multiple processing procedures.

- Efficient Locking Mechanism: Equipped with quick locking and release functions, it greatly shortens the angle setting time, reduces waiting during process switching, and improves overall machining efficiency.

- Smooth Adjustment Experience: The high-precision sine bar is combined with a smooth adjustment structure, ensuring stable and non-jittery angle adjustment. It allows easy fine-tuning of subtle angles, providing more precise operating feel.

- Space-Saving Structure: The compact body design does not occupy excessive machine tool space, making it particularly suitable for processing environments with dense equipment and optimizing workshop layout.

- Stable Performance Output: The all-metal structure and precision assembly process effectively resist vibration interference during machining, ensuring stable and error-free dressing processes.

- Easy Maintenance: The surface is treated with anti-rust technology, making daily cleaning and maintenance simple and convenient, reducing equipment maintenance costs and operational thresholds.

Application Scenarios: Precisely Matching Professional Machining Needs

- Mold Manufacturing and Maintenance: Used for dressing key parts of molds such as cavities and cutting edges to ensure mold precision and service life.

- Precision Part Manufacturing: Adaptable to precision part grinding in automotive, electronics, aerospace, and other fields, ensuring that part dimensional tolerances and surface roughness meet standards.

- Tool and Cutter Grinding: Targets the edge regrinding of milling cutters, drills, taps, etc., restoring tool sharpness and precision, and extending tool service life.

- Surface Grinding and Contour Dressing: Suitable for fine surface grinding and complex contour dressing of various metal materials, meeting high-demand appearance and dimensional standards.

- Fine Machining in High-Precision Processing: Provides stable wheel dressing support in ultra-high-precision machining scenarios such as medical equipment and optical components.

Packaging and After-Sales Service: Comprehensive Protection for Your Procurement Experience

Package Contents

- AP50 Angular Sine Wheel Dresser × 1

- Custom Protective Storage Case × 1 (effectively preventing collision damage during transportation and storage)

- Detailed User Manual × 1 (including full-process guidance on installation, operation, and maintenance, enabling novices to get started quickly)

After-Sales Service

- 12-Month Quality Guarantee: From the date of purchase, if a fault occurs due to product quality issues, free repair or replacement services are available.

- 30-Day Unconditional Return and Exchange: After receiving the product, if it does not meet usage needs or has quality issues, you can apply for return or exchange without reason, ensuring zero-risk shopping.

- Professional Technical Support: An exclusive technical team is available to provide 7×12-hour online consultation, promptly solving various problems encountered in installation and operation.

Shipping Policy

- Fast Shipping: Orders are dispatched within 1-2 working days after payment confirmation, shortening your waiting time.

- Accurate Delivery: Domestic delivery takes 3-7 working days, and international delivery takes 7-15 working days (subject to the destination). All orders are provided with a logistics tracking number, allowing real-time checking of logistics status.

- Shipping Discount: Free shipping is available for orders over $99, reducing procurement costs.

Reviews

There are no reviews yet.